Fume cupboard efficiency upgrades

We have recently completed our largest energy saving project to date, which is expected to save £88,000 and reduce our carbon footprint by 343 tonnes CO2 annually.

£250,000 has been investment in the complete redesign of the ventilation systems and controls for 44 fume cupboards in Chemistry’s teaching laboratories. Energy savings are being made through a combination of measures:

- New high-efficiency fans ventilation extract fans for the laboratories’ fume cupboards, which are 32% more efficiency than the previous models

- Intelligent ‘Variable air volume’ (VAV) controls, which adjust the ventilation system’s input and extraction rates based on the demand from the cupboards

- PIR sensors installed on the cupboards, linked to a warning system reminding users to close the sashes on the cupboards when not in use

- Re-designed ventilation to the chemical storage cupboards, so the majority of fume cupboards can now be turned off when not in use.

- Substantial heating savings, as less heated air is being extracted from the labs. The number of times the complete volume of air in the labs is replaced has reduced from 36 to 10 per hour; in line with current efficiency standards. The labs are also a warmer as a result.

Our Green Week competition winner, Saiyma Iqbal, has designed an interactive display to indicate how efficiently the cupboards are running in each laboratory. Saiyma wins a £100 Oracle Gift Card and will see her design, based on the periodic table, built and installed in both labs.

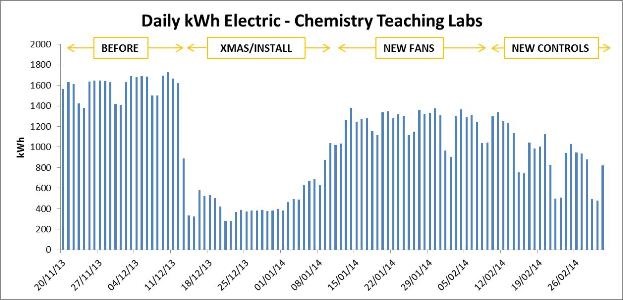

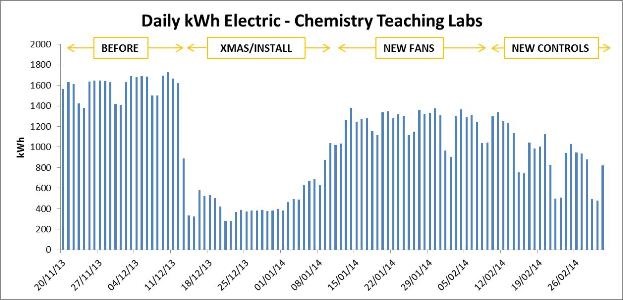

As the graph below shows; we’re already seeing significant energy savings and with over 300 fume cupboards around campus, we are beginning to explore opportunities for similar improvements in other labs, which can make a significant contribution to our 35% carbon reduction target for 2016.

Our thanks go to colleagues in Chemistry, Health and Safety and the Estates & Facilities Projects Team for their patience and support in seeing this through.

This project was partially funded by a £187,000 interest-free loan from Salix Finance. Details of the many other initiatives we have underway can be found at http://www.reading.ac.uk/cleanandgreen/energy